Gambiaj.com – (New Delhi) – More than 100 pharmaceutical companies in India have failed cough syrup quality tests, and a whooping 353 batches of cough syrup did not meet quality standards due to contamination with toxins associated with fatal incidents in the Gambia, Cameroon, and Uzbekistan, according to India Economic Times’ report, citing government data. This report comes after the fifth such alert issued by the WHO since 2022 regarding Indian-made cough syrups.

The report revealed that these cough syrups contained the same toxins found in the medicine linked to over 141 children’s deaths in these countries. The implicated syrups were found to contain Diethylene Glycol (DEG) or Ethylene Glycol (EG), substances previously linked to Acute Kidney Injury (AKI) among young patients who consumed contaminated medicines abroad.

Following the string of deaths overseas linked to Indian cough syrups, the Government of India has directed pharmaceutical companies to adhere to new regulations in an effort to restore credibility to India’s $50 billion pharmaceutical industry. The Central Drugs Standard Control Organization (CDSCO) blames unsecured supply chains and inadequate testing for the presence of these toxins.

“The manufacturer must assume responsibility for the quality of the pharmaceutical products to ensure that they are fit for their intended use, comply with the requirements of the licence and do not place patients at risk due to inadequate safety, quality or efficacy,” stated a directive issued by the Centre.

India’s deaf ear to WHO recurrent alerts on cough syrup contamination

This news comes after a series of global alerts issued by the World Health Organization (WHO) in 2022 regarding cough syrups manufactured in India that were linked to the deaths of over 140 children worldwide. The first alert came in October 2022, when the WHO flagged four cough syrups produced by Haryana-based Maiden Pharmaceuticals.

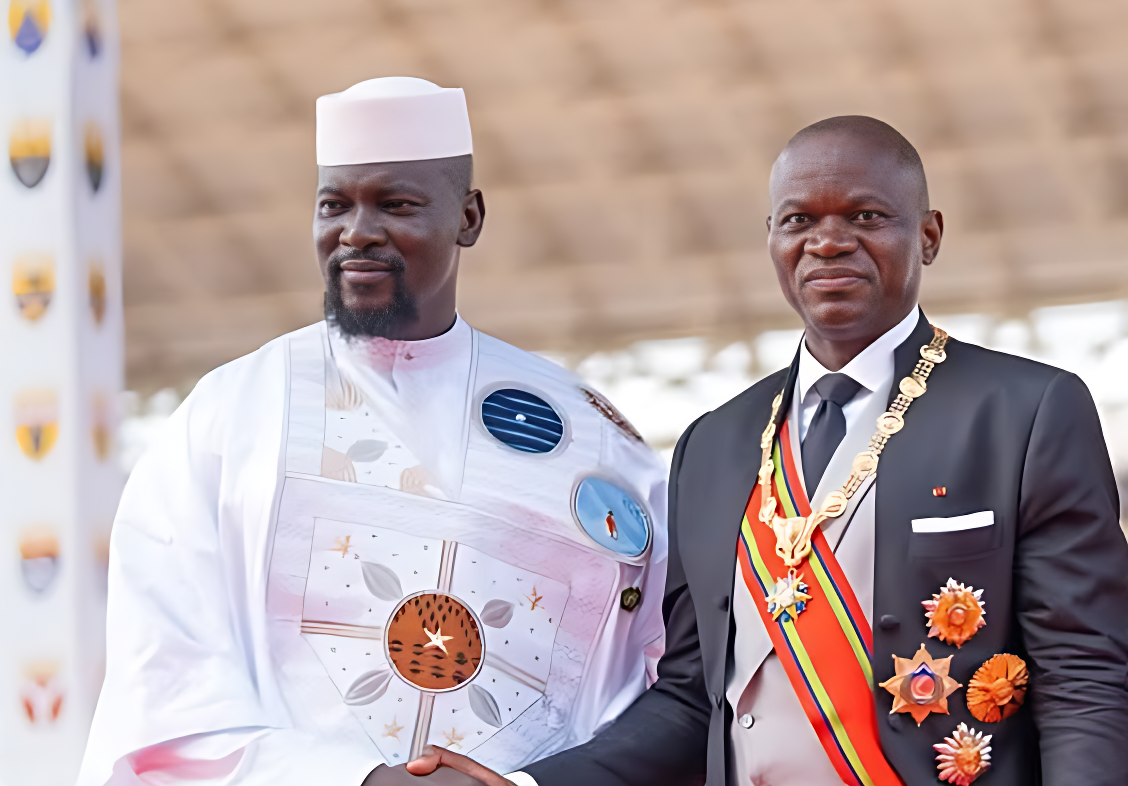

Authorities in the Gambia linked these medications to 66 deaths, primarily from acute kidney failure. In December 2022, the WHO recommended avoiding two cough syrups made by Marion Biotech after Uzbekistan reported 18 child deaths linked to their Dok 1 Max syrup.

Most recently, in August 2023, the WHO issued another alert for a batch of Indian common cold syrup found to contain unacceptable levels of DEG and EG as contaminants. This marked the fifth such alert issued by the WHO since 2022 regarding Indian-made cough syrups.

The new regulations stipulate that companies must conduct thorough testing of ingredients and retain sufficient samples for subsequent verification of each batch before releasing products into the market. India’s drug regulatory authorities have started overhauling the pharmaceutical export approval process in response to global concerns over the safety and quality of medicines originating from the country.

India’s pharmaceutical sector ranks as the third-largest globally by volume, primarily known for its role as a leading provider of generic drugs worldwide. The industry also supplies more than half of the global demand for vaccines and fulfills a substantial portion of generic drug needs in major markets such as the United States and the UK.

The revelations regarding contaminated cough syrups underscore the critical need for stringent quality control measures within India’s pharmaceutical manufacturing sector to prevent similar incidents in the future. The Economic Times report has sparked renewed calls for accountability and transparency in the oversight of pharmaceutical production processes.

Despite the severity of these incidents, the apex drugs regulatory authority is reportedly considering a proposal to waive the requirement for testing cough syrups being exported to major markets like the US, the UK, Canada, the European Union, Japan, Australia, Singapore, Korea, and Switzerland at the prescribed laboratory. This decision has raised serious concerns about the safety of cough syrups manufactured in India.

The Indian government is urged to take immediate action to address these issues by strengthening quality control measures, securing supply chains, and ensuring thorough testing to prevent further tragedies.